Pencoed School, Pencoed

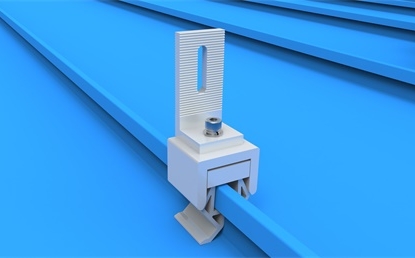

1 Vision worked with Bridgend County Borough Council to install a 25.2KWP solar array comprising of 84 LG Neon 300W solar panels. Our MCS credited solar installations team worked to install, commission and handover this job within 4 days. Due to the profile of this roof our mounting system was Renusol standing seam mounting clamps.

Renusol standing seam clamps are our main preferred choice when it comes to standing seam mounting systems, These clamps are aligned when the cross beam of the roof is tightened. The clamp is then pressed onto the seam as far as possible, the tightening torque then has to be places in such a manner that the standing seams are not affected and the thermal expansions of the metal are not impeeded. Below is a reference image to shwo a standing seam mounting clamp. The clamp mount clips underneath the ridge of the standing seam roof and is then secured in with a bolt trough the frame and then the rail mount is clipped on meaning the rail can be mounted.

As this array was on a school we installed a 40" LG Smart TV which is connected to the inverter and generation meter, This is normally situated in the main office/reception and this shows the generation of the system and a chart showing all panel online/offline status. This is useful for the main office staff to monitor the system and report any issues back to us and we can then arrange a maintanence/repair call out.

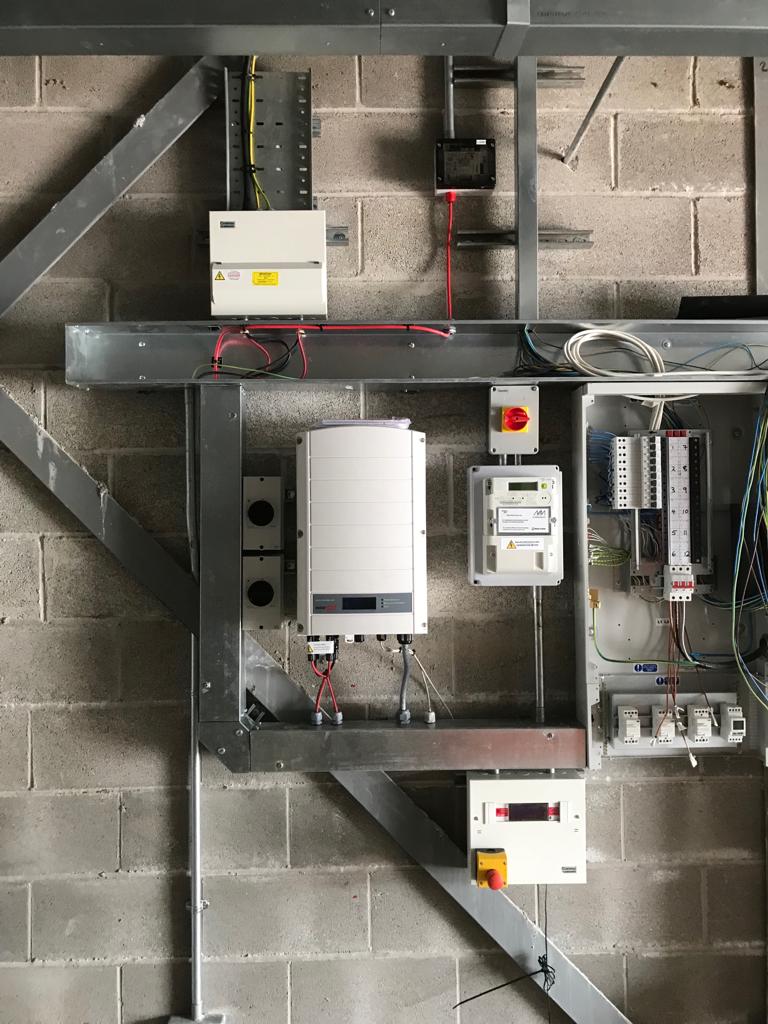

This system is SolarEdge meaning that it uses SolarEdge optimisers to optimise the system, There are different types of optimisers which have different wattage outputs. P300, P600 and P700.

P300 - 300WATT, 1 optimiser per 1 panel

P600 - 600WATT, 1 optimiser per 2 panels

P700 - 700WATT, 1 optimiser per 2 panels

This system uses P700 optimisers which only requires 1 optimiser every 2 panels, There is a good reason there is 1 optimiser per 2 panels. This is because if one panel was to go down then the optimiser creates a 'bridge' to connect the two panels surrounding the offline panel generating, this meaning that the system is still generating even though one panel has shut off.